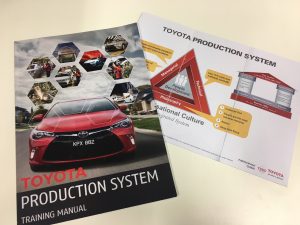

On the 16th of August 2018, I had the privilege of attending an introduction to the Toyota Production System at their Australian HQ in Port Melbourne. The following day I joined a site tour of their Spare Parts Distribution Warehouse in Altona.

The images below were taken in the Spare Parts Distribution Centre. Each ‘ERP Whiteboard’ has a very specific function, these include labour allocation, delivery unloading progress monitoring, vehicle loading and spare parts picking job allocation.

The aim of the boards is to get information out of the ‘black box’ (computer) and into the hands of the team. The Toyota Production System was the foundation of the larger Lean Manufacturing movement and shares many common themes, including placing a high priority on visual management. The aim of a visual management system is to allow anyone to see, at a glance, if the day’s work is on schedule, or within the appropriate quality range.

Find out more about the Toyota Production System here.

Find out more about Lean Manufacturing here.